jawcrusherjawcrusherjawcrusher

jaw crusher百度百科

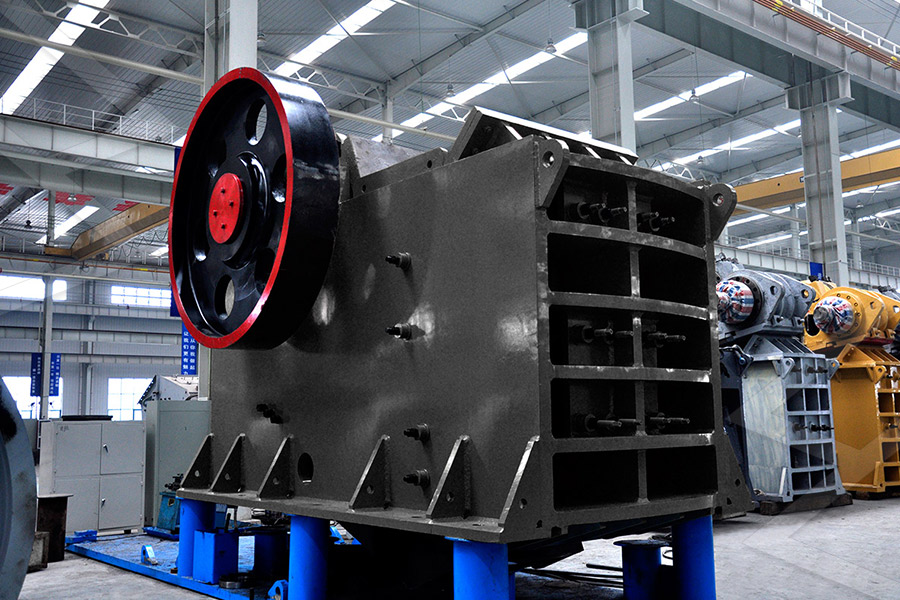

Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is 展开The main fields of application for a jaw crusher include building materials, mineralogy and metallurgy, ceramics and glass, materials science and environmental analysis They Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

Jaw Crushers Manufacturer Puzzolana

4 天之前 Explore Puzzolana's cuttingedge jaw crushers in India designed for superior performance and efficiency As a trusted manufacturer, we bring you innovative solutions 颚式研磨仪应用领域 A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is primarily used in laboratories and pilot Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

Eagle 2036 Portable Jaw Crusher Eagle Crusher

8’ 6” / 26M Travel Height 13′ 5″ / 41M For complete technical specifications, download our spec sheet DOWNLOAD SPEC SHEET CONTACT EAGLE REQUEST A QUOTE Eagle Crusher's 2036 5 天之前 MJ55 Designed around our proven, highperformance Cedarapids® JW55 jaw crusher, the MJ55 Modular Jaw Crusher is designed for large quarries or contractors that want a stationary type Cedarapids JW55 Jaw Crusher MPS

Jaw Crushers Parker Plant

5 天之前 Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger model2024年6月6日 5 discharge fineness Jaw crusher, as coarse crushing equipment, has larger discharge fineness, usually below 300350mm (depending on the model) Impact crusher, as medium or fine crushing equipment, naturally has smaller discharge fineness Here, we should notice that due to different material properties, the discharge fineness 7 Differences Between Jaw Crusher and Impact Crusher

Jaw Crusher, Jaw Crusher price, jaw crusher

2024年6月14日 Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, advanced manufacturing 5 天之前 Available in a variety of sizes and configurations, the HydraJaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver highcapacity crushing and reliable performance for increased operational productivity and profitability Our diverse line of industryleading jaw crushers offers producers the latest in jaw crushing technology Jaw Crushers Astec

® C Series™ jaw crushers

® C Series™ jaw crushers are designed modular to save time and installation costs They can be installed within a few days, minimizing onsite engineering and fabrication The jaw crushers can be upgraded with crusher automation that enable monitoring and adjusting the settings of a feeder, crusher, and conveyor remotelyadvanced kinematics of swing jaw reinforced design of swing jaw to take up peak loads crushing jaws can expand freely compact and reliable design quick and easy exchange of wear parts easy adjustment of thyssenkrupp jaw crusher thyssenkrupp Polysius

J960 Portable Jaw Crusher Mobile Crusher Tracked

4 天之前 The Finlay® J960 Portable Jaw Crusher is a compact and aggressive mobile jaw crusher that has been designed with the customer and operator in mind The machine has been redesigned with improved all round preventative maintenance and serviceability access points The heartbeat of the machine is a robust direct driven 900 x 600mm 2022年9月23日 Crusher Wear Parts not only supplies wear parts but offers jaw liner accessories including: cheek plates, movable wedges, stationary wedges, toggle plates, and toggle seats * Improved production * More accurate product sizing * Better wear metal utilization and lower discard weight * Longer wear part life * Lower overall operating costsJaw Liners Crusher Wear Parts

How to improve jaw crusher performance and productivity

2020年3月30日 That is why it needs to be monitored throughout the crusher’s lifecycle As excessive wear can cause a 10–20% reduction in production, it is important to find the optimal time for the jaw turn or change in terms of cost and benefit Again, with the same scenario with C130, we would have approximately a 70 stph reduction in production, in 2024年2月5日 In jaw crushers, the crushing force is generated by the movement of the movable jaw plate towards the fixed jaw plate This force is a result of the mechanical pressure created by the eccentric shaft and transmitted through the toggle plate The interesting thing is how these forces are applied to the materialHow Does a Jaw Crusher Work? A Simple Guide JXSC

Sandvik CJ411 SingleToggle Jaw Crusher For High

Motor power 132 kW (200 hp) Sandvik CJ412 singletoggle jaw crusher is engineered for the toughest applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost CJ412 Features Product dataCJ613 Capacity (by hour) 330 960 mtph (364 1,058 stph) Feed opening 1,300 x 1,130 mm (51 x 45 in) mm Motor power 160 kW (250 hp)Sandvik CJ613 SingleToggle Jaw Crusher With A Heavy Duty

20+ Common Faults of Jaw Crusher with Solutions MC

2024年6月14日 4 The relative position of the teeth groove of the moving jaw and the fixed jaw is wrong; 5 The voltage is too low; 6 The clearance between the movable jaw and the fixed jaw is too large, resulting in the rotation of the outer ring of the bearing Solution: 1 Replace with a new crusher of appropriate model; 22023年2月16日 Jaw plates are the parts of the jaw crusher that direct contact with the material being crushed They are rectangular in shape and are designed to fit around the crushing chamber of the jaw Jaw Plates: Everything You Should Know

Jaw Crushers Price MadeinChina Manufacturers,

The cost of a Jaw Crushers Price can vary widely depending on its size, capabilities, and complexity Most of the price of Jaw Crushers Price ranges from US $ 900 to $ per Piece It's important to research and compare different models and features to find the best Jaw Crushers Price for your needs and budget Q2016年12月19日 14 Crusher Size and Power rating: The size of a jaw crusher is usually expressed as gape x width The common crusher types, sizes and their performance is summarized in Table 11Currently, the dimension of the largest Blaketype jaw crusher in use is 1600 mm x 2514 mm with motor ratings of 250300 kW“Computer Aided Design of Jaw crusher” 911 Metallurgist

RM J110X Mobile Jaw Crusher RUBBLE MASTER

It is the heaviest jaw in the industry This 44” x 28” (1,100 x 700 mm) hydraulic jaw doesn’t cut corners so that you can feed bigger pieces A 10% deeper jaw box gives you more crushing action Don’t Get Stuck Reverse Crushing Keeps You Crushing Crush difficult materials or unblock your crusher with ease2022年11月21日 Our solutions for the hardest jobs Fields of application and design characteristics They are used in mines and quarries as primary crushers to crush blasted rockpile,Industrial Solutions Jaw crushers ThyssenKrupp

How Does a Jaw Crusher Work Jaw Crusher

2024年6月16日 Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to Retsch Products Milling Jaw Crushers The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants Benchtop UnitJaw Crushers high quality and reliability from RETSCH

Key Differences Between Jaw Crusher And Impact Crusher?

2022年11月14日 The main differences include: Impact crushers are better at manipulating hard materials while jaw crushers are better at crushing softer materials Impact crushers produce a more uniform size while jaw crushers create a more jagged size This makes impact crushers a great choice with projects that require certain specs on aggregate usageJaw crusher for sale Production Capacity: 1–1200 t/h Feeding Size: 125–1200 mm Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc get Jaw Crusher For Sale Jaw Crusher Jaw

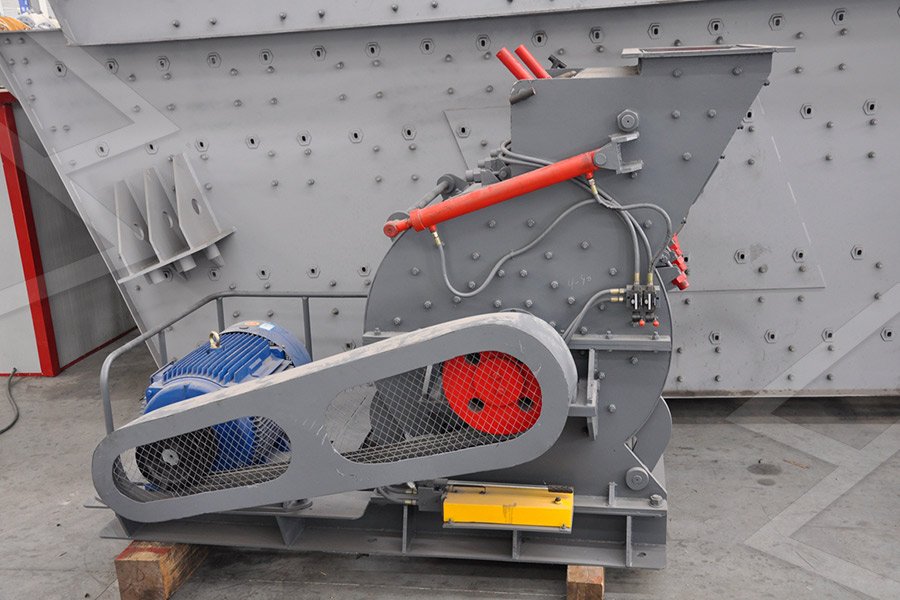

Hammer Crusher VS Jaw Crusher Which Is

Hammer Crusher is mainly composed of casing, rotor, main shaft, lining plate and striking plate Hammerhead is the key vulnerable part Jaw Crusehr is composed of frame, transmission device, adjusting device, Consistent crushing at high throughputs – our Jaw Crusher EB is the solution for crushing mediumhard to very hard materialsJaw crusher EB

J1170 Stone Crusher Mobile Jaw Crusher Finlay

4 天之前 The Finlay® J1170 Stone Crusher is a compact and aggressive tracked jaw crusher The heartbeat of the machine is a robust hydrostatically driven jaw chamber which provides high capacity with large reduction ratios The jaw chamber configuration can be set up specifically for either processing construction demolition debris or quarrying 颚式研磨仪应用领域 A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is primarily used in laboratories and pilot Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

Eagle 2036 Portable Jaw Crusher Eagle Crusher

8’ 6” / 26M Travel Height 13′ 5″ / 41M For complete technical specifications, download our spec sheet DOWNLOAD SPEC SHEET CONTACT EAGLE REQUEST A QUOTE Eagle Crusher's 2036 5 天之前 The JW Series is engineered for portability and ease of use The rugged design delivers the reliability you can expect from Cedarapids They feature a hydraulically actuated wedge system that allows Cedarapids JW55 Jaw Crusher MPS

Jaw Crushers Parker Plant

5 天之前 Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger model